Torque Tightening

There are two methods of torque tightening, manual (hand) tightening and hydraulic tightening. Both methods use the applied force to turn the nut(s). The loads are induced through the threads of the bolt and nuts, physically stretching the bolts and compressing the gasket which maintains the residual bolt load.

The varying frictional conditions between the threads and the nut face and the flange causes large irregularities between the applied force and the residual bolt load.

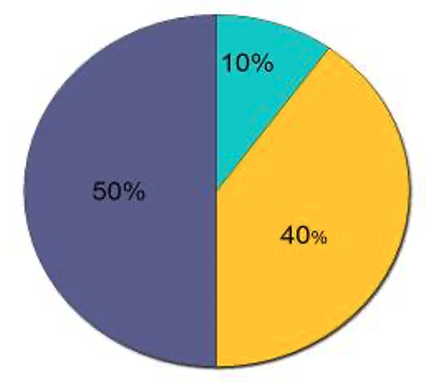

Different machined surface finishes and material types all change the effects of friction. Depending upon the lubricant used:

- Up to 90% of the applied load could be lost due to friction, only 10% of applied torque value could end up being of any useful bolt load.

- 50% could be wasted in overcoming nut face friction.

- 40% could be wasted in overcoming friction between the threads of the bolt and the threads of the nut.

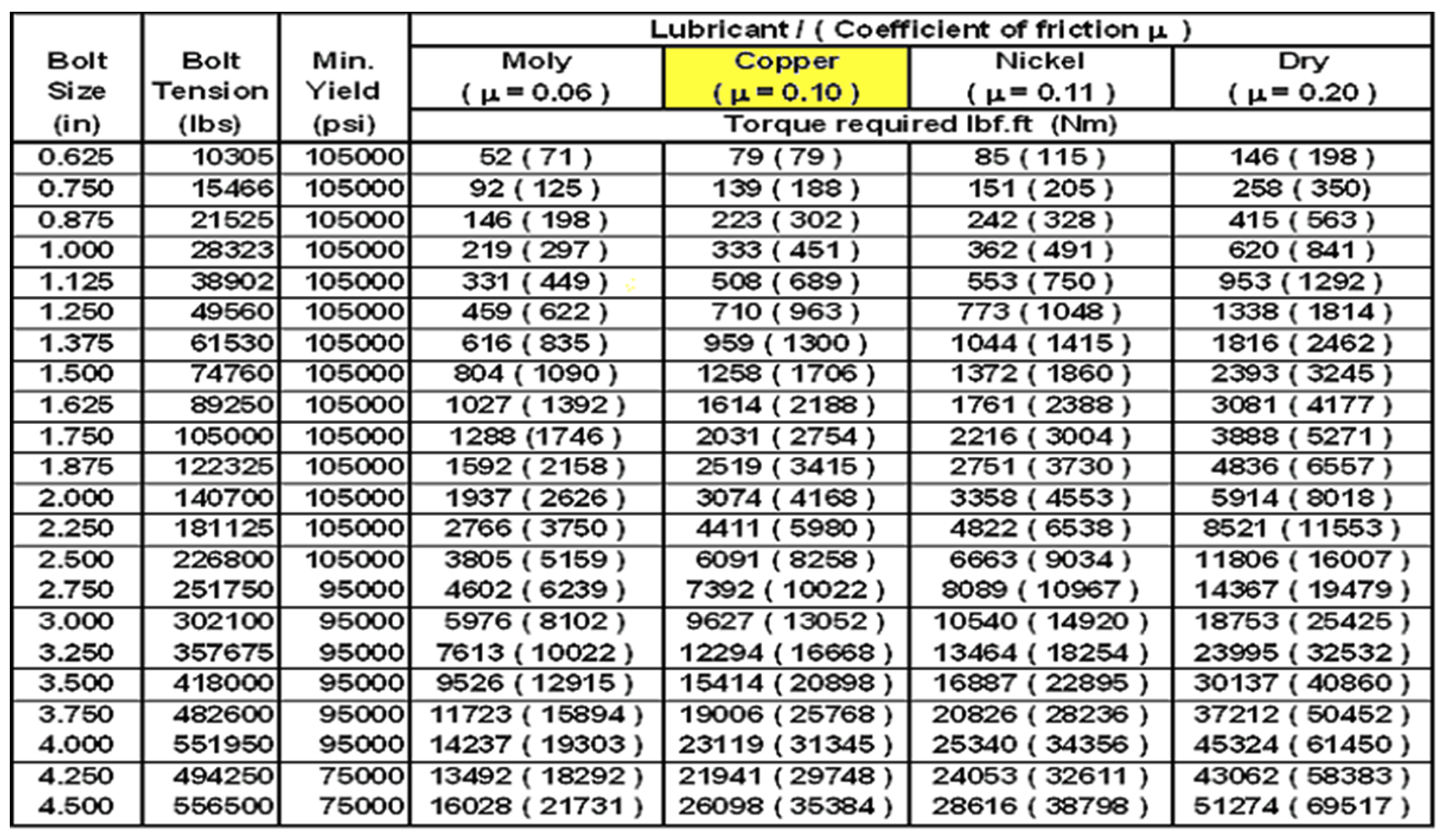

Different lubrications will result in different coefficient of friction on the bolts. Do not use other than the specified lubrication and never mix the lubrication together.

Once joint has been correctly cleaned and assembled using all the correct materials, the bolts are then tightened in the correct manner.

When establishing the correct torque settings, the torque required to achieve a given bolt load will be affected by the following factors:

- Nominal bolt diameter.

- Bolt and flange materials.

- Bolt lubrication (if used).

- Thread form and thread pitch.

- Assembly conditions (misalignment / pipeline in tension).

The use of flogging spanners are inaccurate and are not recommended without the permission from an authorised person.

Torque tightening is a specialised skill and only competent personnel should carry out this work.

Above is a table to show the importance of lubrication and by using a lubrication with a known coefficient of friction how it can impact heavily on the residual bolt load and the amount of torque required.

BOLT TIGHTENING PROCEDURES SHOULD BE MAINTAINED

4 Bolt Hole Sequence

A Handy Tip! “Plus 4 Till No More”

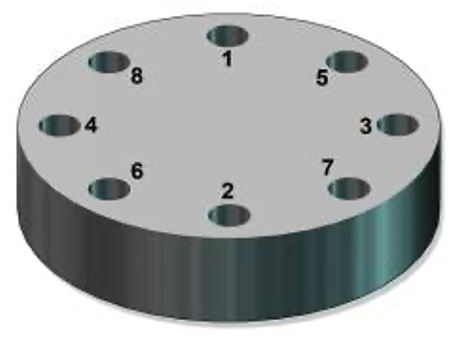

8 Bolt Hole Sequence

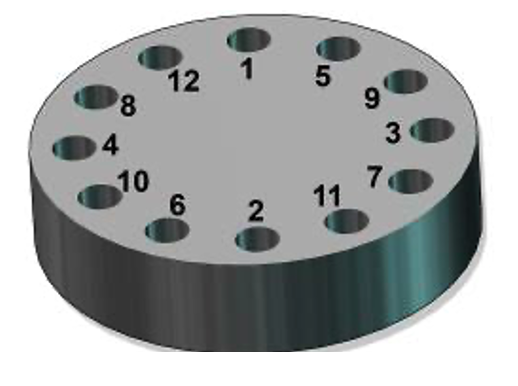

12 Bolt Hole Sequence

Bolt Sequence for Torque Wrench Applications

Bolts are normally numbered in a clockwise direction around the flange:

- 4 Bolt Flange 1-3-2-4

- 8 Bolt Flange 1-5-3-7-2-6-4-8

- 12 Bolt Flange 1-5-9-3-7-11-2-6-10-4-8-12

- 16 Bolt Flange 1-9-5-13-3-11-7-15-2-10-6-14-4-12-8-16

- 20 Bolt Flange 1-13-5-17-9-3-15-7-19-11-2-14-6-18-10-4-16-8-20-12

- 24 Bolt Flange 1-9-17-5-13-21-3-11-19-7-15-23-2-10-18-6-14-22-4-12-20-8-16-24

- 28 Bolt Flange 1-13-21-5-17-9-25-3-15-23-7-19-11-27-2-14-22-6-18-10-26-4-16-24-8-20-2-28

- 32 Bolt Flange 1-17-9-29-5-21-13-25-3-19-11-31-7-23-15-27-2-18-10-30-6-22-14-26-4-20-12-32-8-24-16-28

Correctly numbered bolts should result in all the odd numbered bolts around the right hand side of the flange and all the even numbered bolts around the other side.

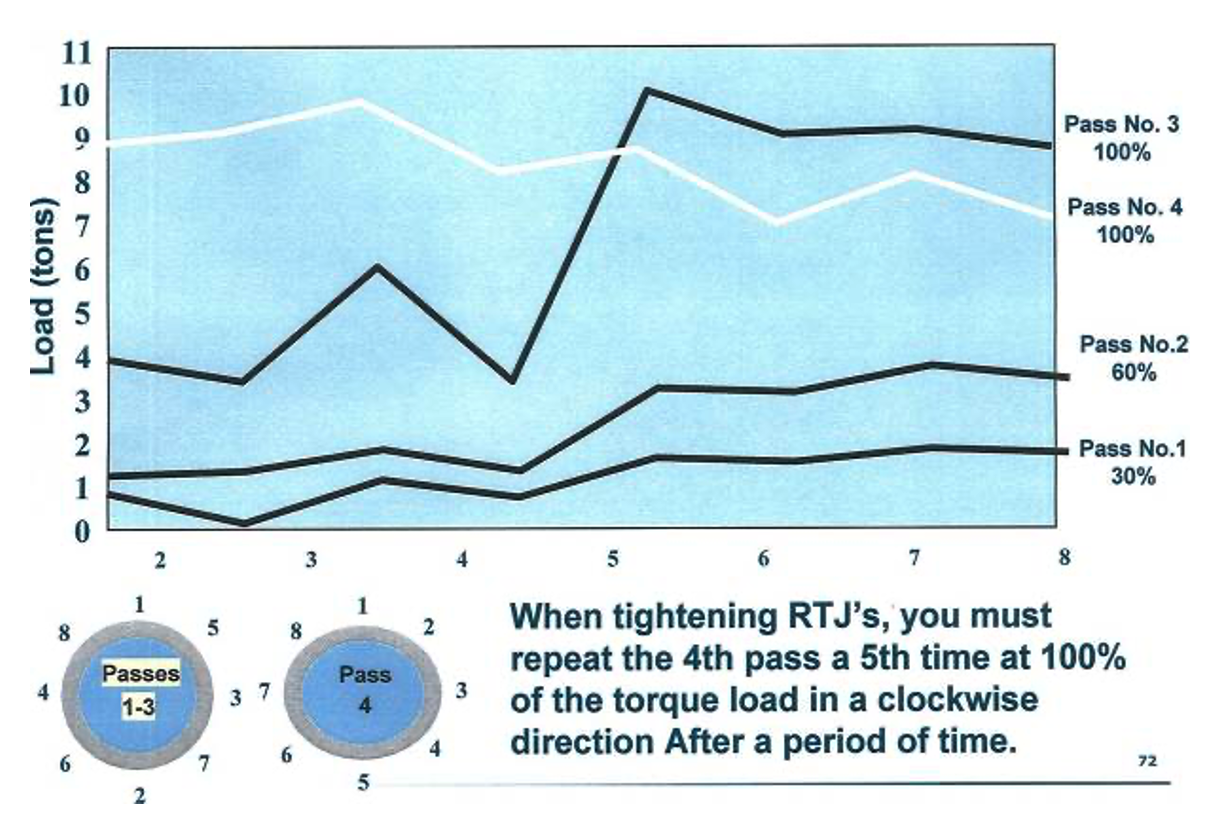

Tightening must be carried out in a minimum of four passes.

Passes 1 – 3 following the numbered bolt sequence and pass 4 tightening adjacent bolts sequentially clockwise around the flange (when tightening a RTJ flange, it is required that we repeat the 4th tightening sequence a 5th time after a period of time).

The specified Applied Torque Value must be applied gradually in order to prevent local over tightening of the Gasket. The recommended percentages to Torque Value to be applied in each pass are:

- Pass 1 30% of final value in numbered bolt sequence

- Pass 2 60% of final value in numbered bolt sequence

- Pass 3 100% of final value in numbered bolt sequence

- Pass 4 100% of final value in adjacent bolts

Torque Tightening – Do’s and Don’ts

Do’s

- Tightening procedures can be made available.

- Numbering the studs / studbolts using the correct sequence will assist in tightening of the flanges. Bolt tightening methods are shown in the previous pages.* When tightening any bolted joint, the torque value must be obtained.

- Remember to clarify the coefficient of friction of any lubricant being applied.

- Follow all safety procedures for the equipment being utilised.

- Always switch off pump when moving wrench.

- Keep fingers away from reaction area.

Don’ts

- Do not use individual bolts to pull the joints together as this can damage the gaskets, bolts or the flanges and lead to a potential loss of integrity in the system.

- Care shall be taken when applying loads with smaller bolt diameters, such as where the bolts are less than 1” in diameter.

- Hold the wrench when setting the pump pressure.

- Do not leave pressure trapped in the hose overnight.

HYDRAULIC TORQUE TIGHTENING SHOULD BE CARRIED OUT ONLY BY TRAINED AND COMPETENT PERSONNEL TO THE STANDARDS LAID DOWN BY THE ENGINEERING CONSTRUCTION INDUSTRY TRAINING BOARD NATIONAL SKILLS DEVELOPMENT SCHEME Unit No’s: MJI10 & MJI 19

SAFETY NOTE!! HYDRAULIC TORQUE WRENCHES WORK AT PRESSURES RATED AT 10,000psi MWP (100psi will break the skin) BE AWARE OF PINCH POINTS – HIGH REACTION FORCES